- 58 Posts

- 159 Comments

17·3 days ago

17·3 days agoHow about early Hitler?

81·3 days ago

81·3 days agoNice.

61·6 days ago

61·6 days agoCalculating the number of hours I had left on Earth, and realizing that every hour I spent fretting about shit that doesn’t matter is an hour I won’t spend having the best possible time on this dirtball with my family and my friends before I kick the bucket.

Once I “let go” and decided nothing really mattered, it felt like my whole body finally deeply relaxed for good.

6·6 days ago

6·6 days agoNo, it’s the smell at the pump. Nothing to do with how the engine feeds itself. Yeah, leaded gasoline smelled different. “Sweeter” or something. Maybe it wasn’t the lead, and maybe whatever replaced the lead inside modern gasoline is what smells different, but it definitely isn’t the same.

It’s not like gasoline smelled better, it’s just that I remember smelling that smell when the entire family went on summer holidays and we kids were allowed to stretch our legs while our dad gassed up the car. Good times and good memories!

10·6 days ago

10·6 days agoI’m way past that point.

Missing your youth first hits you when you start having small health issues you didn’t have before. And then it gradually gets worse. There’s no crisis about it.

33·6 days ago

33·6 days agoNah. I just miss my youth.

27·6 days ago

27·6 days agoCome to think of it, I miss school and I miss the military. They were both godawful, but I was young.

47·6 days ago

47·6 days agoDon’t.

Because what he left out is that for those 5 minutes of peaceful enjoyable smoking, you have to endure the rest of the day craving, smelling like dog shit, getting an earful from your supervisor at work because you’re constantly out for a smoke, spending your life’s savings at the tobacconist, and driving 20 miles in the middle of the night to find a pack of smokes in a convenience store in the middle of the night when all the other stores are closed. Not to mention long term health issues of course.

That’s an expensive 5 minutes of enjoyment, trust me on that one.

64·6 days ago

64·6 days agoThe smell of leaded gasoline.

The smell of a fine cigar: I quit smoking 14 years ago but I miss that.And I’m 200% sure they were awful.

9·6 days ago

9·6 days agoExactly.

People don’t root for feature-poor stuff because it’s unique but because the features it’s missing - that they want - preclude the hardware and the hardware maker from slipping in features that they don’t want.

551·6 days ago

551·6 days agoI think it’s also a sign that people want devices that don’t come from Big Data, aren’t online and aren’t designed to put them under surveillance and invade their privacy.

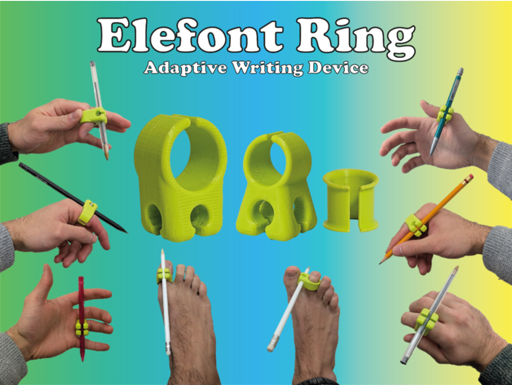

Finished print 🙂

the frame rate is ass

Well, in my case, I just bolted an el-cheapo supermarket-bought webcam inside the printer’s enclosure. It’s terrible in every way: it has fixed focus and the bed of the printer isn’t in the focus plane, it has terrible rolling shutter and no manual exposure control.

The webcam is connected to one of the production servers nearby that serves up the video as a MJPEG stream using Motion. It’s Motion that limits the framerate to 2 fps, and I configured it that way on purpose: I just need the camera to know whether something terrible has happened to the print and I should stop it remotely - like parts lifting or coming fully unstuck from the sheet, extruder collision… I don’t need quality video for that, so I chose the low framerate and poor resolution primarily to save bandwidth on my home internet, which is kind of crap because I live deep in the forest 🙂

I’m much more interested in whatever mechanical contrivance you’re printing parts for, there.

It’s a bit complicated to explain, but to make it simple: the top parts are optical couplers. They have a slot and a dovetailed circular rail inside that you can’t see because it’s buried in the support. The bottom parts are shutters that ride in the rail and block off more or less of the light in the side of the couplers that has the rail, and have a lever on the other side. The side parts are just mounting clips to hold the couplers onto the optical measurement instruments they’re meant to be mounted on.

Those parts cost cents to make and work just as good as multi-hundred dollar professional optical attenuators, and they’re a lot more convenient for a quick manual adjustment that doesn’t require a precise number of decibels of attenuation.

36·9 days ago

36·9 days agoIANAL but my attorney once told me he witnessed a guy defending himself in court for involuntary manslaughter saying “I didn’t see the red light because I was drunk.”

1·10 days ago

1·10 days agoSo far our (new) machine is performing well. We’ll see how it fares in the long run. That’s one of the advantages of having my company purchase it: it’s getting a beating for work purposes, so I can test it properly before buying one for myself 🙂

1·11 days ago

1·11 days agoI think the pros/cons come down to what you need a printer for. If you print mostly flat things, a bedslinger is fine. If you print large parts with sketchy bed attachments like I often do, a coreXY makes a lot more sense. You have no idea the amount of filament I wasted on giant brims and rafts to keep parts from flying off the sheet - not to mention the time it takes to print them.

And then of course, the Prusa XL in particular can be outfitted with up to 5 separate extruders. It has nothing to do with coreXY but it was a big part of why we bought it.

1·12 days ago

1·12 days agoI haven’t tried pushing the speed yet. I’ve been playing with multi-color and multi-material prints, as well as long tall thin prints that were kind of impossible on the Mk4. And when I’m not playing with that, I’m running it almost 24/7 because I have to produce sets of parts for our production floors asap and each set takes about 20 hours.

But soon the machine will be more available and I’ll play with it some more.

3·12 days ago

3·12 days agoThat’s true. The Prusa XL is larger than our Prusa Mk4 with the enclosure, but still fairly comparable. However, the XL’s build volume is kind of… staggering in comparison.

21·12 days ago

21·12 days agoThe Prusa XL doesn’t lack rigidity. That thing is build like a tank. It feels a lot sturdier than the Prusa Mk4.

Then again, I guess they’re not in the same category…

Another reason not to use Apple.

AI search can fuck right off.