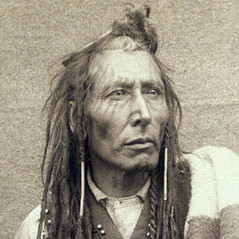

Contractor installed this convoluted p-trap + elbow for the washer, and I’m not sure if it’s up to code. Can you confirm and more importantly explain why or why not it’s compliant?

I manufacture electrical outlet covers for a living…day in and day out, pressing the “make outlet cover button”, it’s incredibly technical. Anyway, you house just seems to be off by 25 degrees or so. I would just rotate it back to fix all the problems I see.

Not a plumber but I am an inspector. This will not pass in Chicago or Illinois.

No trap will form.

No, and the electrical outlets really don’t help.

I’m no plumber, but I’ve done a lot of DIY around the house. I wouldn’t be concerned with the ptrap, probably. I’d be concerned with brand new plumbing with nonstandard adapters hanging over a bunch of exposed electrical.

Holy shit, I didn’t even notice the multiple abominations with electrical connections in that picture, I was mesmerized by the plumbing madness.

You got a turdbo charger!

Poop-de-loop.

Lol. No. Gonna get syphoned out ever time a toilet flushes past that or every time it pumps. No air gap/ directly connected prohibited by codes in most places. I mean it’ll work until it doesn’t. The proper way to do this is with a laundry tub dumped into a proper vented container/basin pump. Or run a drain over from that other pit and put a 48" stand pipe with a 2" trap.

So draining against gravity is bad. The electric outlet cover should be screwed into place and if that’s a dryer vent the lint will collect and clog creating a fire hazard. In sorry, but, that whole setup is janky.

Edit: oh jeeze you have a whole outlet hanging out too.

Edit: I saw your other picture, I too am no plumber, but, none of that looks right

UPDATE thanks all for the comments, just a few clarifications and updates:

-

all electrical work is work-in-progress, we’re finishing it up tomorrow, it’s still an active worksite. The old outlet and old bx wiring is being removed, we’ll only have the newer wiring (and of course all outletd will be in their gangboxes and covers will be on)

-

the dryer vent will be changed and installed without sag when we finalize

-

the 4" abs drain connects to the old one with a rubber fernco gasket, those do require hose clamps and they’re up to code (though the top clamp could be straightened!)

-

the water lines are pex, they’re all good

-

we don’t have a choice but to push the water up with the washer pump - the drain evacuates to the city sewer around hip level in that basement

The worries for me are really the 90° out of the sump pump and the other 90° into the drain column, shouldn’t that be a downward Y? And the double S p-trap, is it creating some risk?

-

I’m sorry but … what an absolute mess

You mentioned that your main drain is a bit higher than the floor of the basement. I have the same situation, my drain is about two feet off the floor of my concrete basement. The washing machine drain was placed to drain towards the lowest point of the main drain. Everything else in the house with a drain is in upper floors.

I’d rearrange the plumbing to build a drain as close to the four foot level as possible for the washing machine … instead of trying to build a solution 6 or 7 feet up in the air … you’re asking for trouble if you are making your washing machine drain up to a high point.

I remember once renting a place that was an old house with a brand new concrete basement … the main drain was close to ground level that went to a septic tank and field. Their solution was to install the washing machine in the basement, drain down to the floor level, then to a grey water pump unit in a big box that was 3x3x3 feet … and that pushed the water up to the main drain. I don’t think washing machines are meant to push water that high up and you will probably constantly have a bit of grey water backing down to the washing machine.

I’ve got a similar situation to your rental for my basement (the main floor drains separately). There’s a macerator/pump combo in an 8ish gallon tank in a pit cut through the foundation (lined with concrete) that elevates to the main drain outside the house. The pump failed a couple years ago and was not fun to deal with. Luckily it was exclusively laundry that day. Everything connected to it is vented.

When we get pushed to connect to sewer (one way or another), my plan is to get a bit silly and connect at the lowest level so we can avoid the pump for the future.

When you do get that connection … go the extra step and install a ‘backwater prevention valve’ … it’s a giant one way valve that is attached to the main drain line as it leaves the house.

It allows water to always easily flow out but if it ever happens that water back flows into your house for some reason … the valve will stop any flow from entering your house.

I’ve always planned to get one but my situation is too difficult to install one.

That does seem pretty obligatory. We have the same thing on our irrigation (don’t want irrigation water backflowing in to the drinking water, and also it’s required).

We are at the top of a hill and everything flows down from us to the entire neighborhood, so that is another good check on the issue.

I’m pretty sure one of the 90 degree angles could be done away with.

The top one, where the washer drain comes in? Or further down?

I think that I could tie it directly into the main. but I’m also incredibly fucking high. so you may want a second opinion.

Not a plumber but, I have to ask. …

The black snakey pipe that does a loop is the drain line? And the washer drains into it from far below against gravity through that thin flexible hose? And it is held on with a hose clamp at the end? I’m no expert, but I wonder about those things…

The hot and cold inlet lines also, I’ve been told always fail eventually and that you should use the metal ones instead.

And is that silver ducting the drier vent? If so, that’s a problem too.

The hot and cold inlet lines also, I’ve been told always fail eventually and that you should use the metal ones instead.

You’re probably confusing Pex for CPVC. PEX is fine (even if I have a preference for copper I have to be real here).

It’s not the pipes I meant, but the flexible hookup hoses. They make metal ones, and I’ve been told they are more reliable then the rubber (vinyl?) ones that these appear to be.

Oh yeah, that I agree with! I’ve had good luck with OEM rubber hoses from LG in the past, but have since replaced them with stainless steel braided hoses indeed!

For the record he also connected the sump pump pipe like this, with a 90° - shouldn’t it be a downward Y instead?

Did you pay money to this person?

Again with the hose clamps. I’ve never seen a real plumber connect things with hose clamps.

It’s totally normal to use hose clamps in this situation. This a PVC to Cast Iron connection. That’s the only way to do it.

The small clean-out is kinda fucking dumb though. And the big hose clamp looks like it’s installed wrong. Can’t possibly be tight enough and be at an angle like that.

I stand corrected. I checked where my plumber had connected pvc to the iron stack, and it does use hose clamps but as part of something a little more convincing. It’s basically a sleeve with 4 hose clamps mounted on it.

Me neither. Good catch. Hose clamps are best on hoses.

deleted by creator

Get that flammable plastic bullshit exhaust duct the fuck outta there.

What plastic duct? It’s a standard foil one, but had a break in a couple of spots and since we’re replacing it by a new one next week, we have a piece of tape on it… Am i referring to the wrong thing?

That foil thing is covered in plastic. It can ignite if any of your dryer lint burns. Get rigid metal.